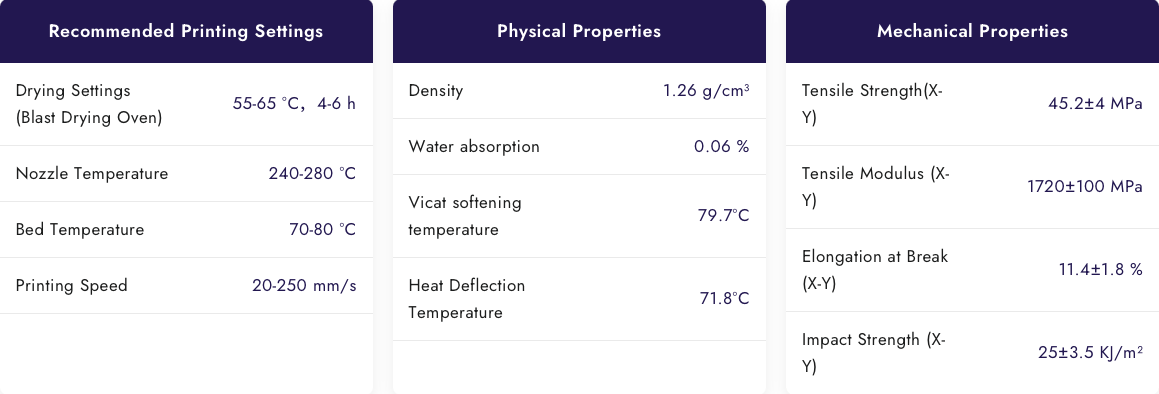

PETG-CF

100,00 ₾PetG Translucent (Qidi)

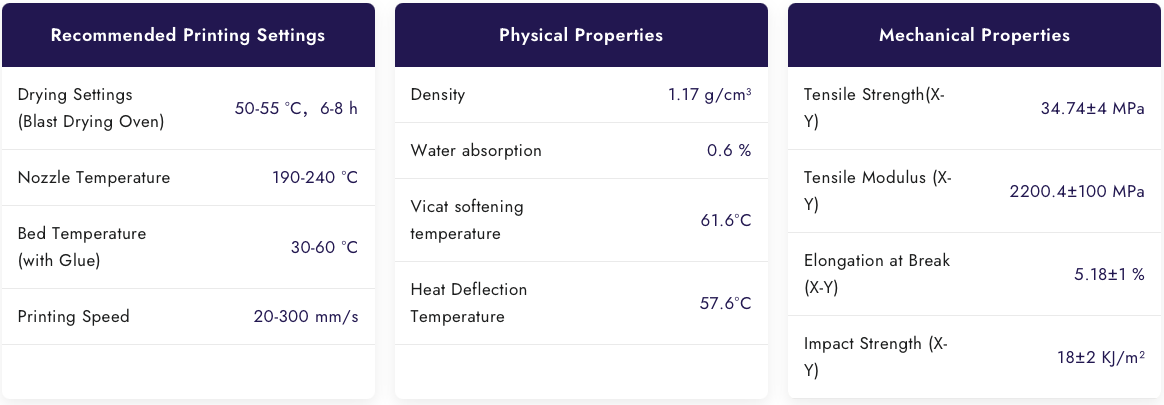

PLA Basic (Qidi)

PC/ABS-FR Filament

- Excellent Flame-resistant

- Tough and Durable

- Comes with High Temperature Spool

- Diameter: 1.75mm +/- 0.02mm

- Enclosure Printers Required

- Active chamber heating Required

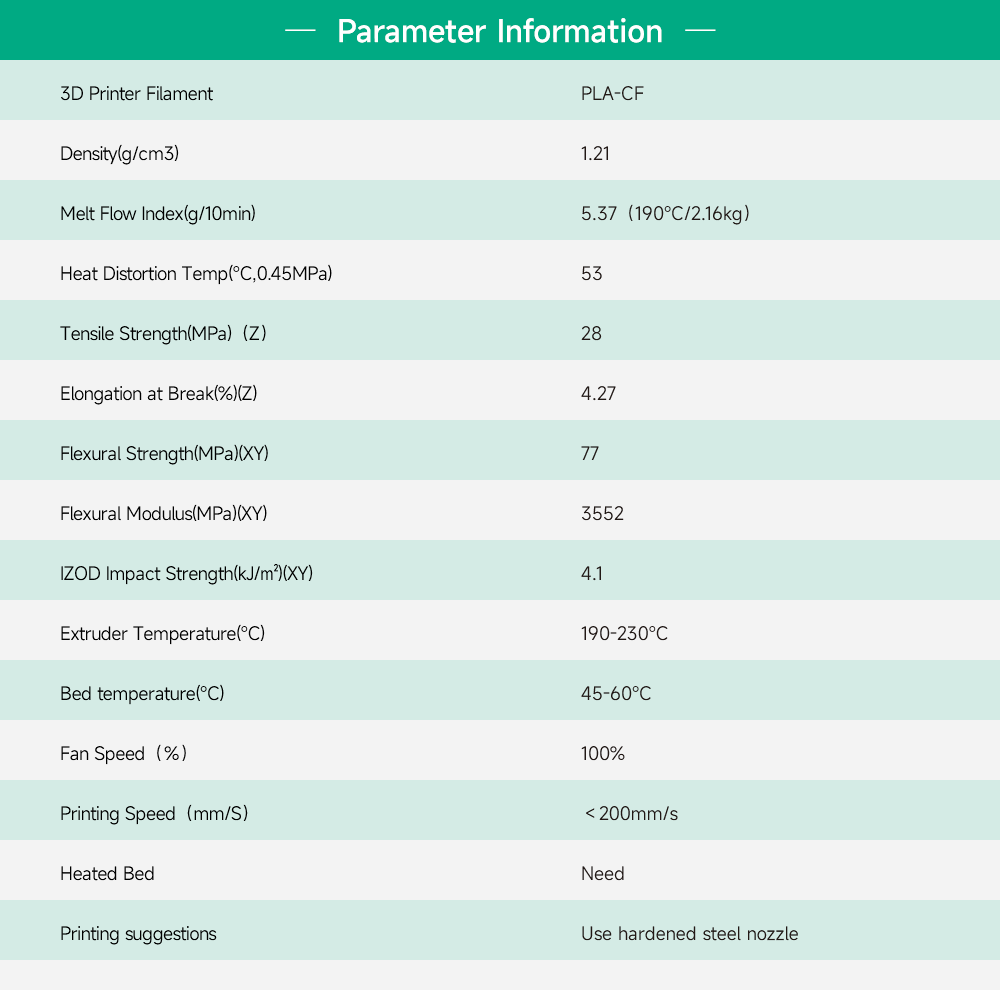

PLA-CF

QIDI ASA-Aero is a type of lightweight 3D printing filament, specifically developed for the fields of aircraft models, ship models, drones, etc. ASA-Aero controls the foaming ratio of the material by adjusting the nozzle temperature during the printing process so that the density of the material extruded by the nozzle can be adjusted within a certain range. With this technique, it is easy to reduce the weight of the model. In the best-case scenario, the model weight can be reduced to 50% of a model printed with ordinary ASA. In addition to that, the matte texture of the printed surface can reduce the visibility of printed layers and thus give a smooth surface finish.

- On-Demand foaming technology QIDI ASA-Aero is a type of ASA filament that will start foaming with the aid of a blowing agent during the printing process. The blowing agent is in an unexcited state in the ASA filament before printing, During the printing process,by adjusting the printing temperature, the foaming ratio of the blowing agent can be easily controlled. The maximum foaming ratio can reach 250%.

- Meanwhile, QIDI ASA-Aero retains the original UV aging resistance and high heat resistance of ASA material, which is suitable for long-term use in high-temperature outdoor environments.

| Recommended Nozzle Diameter | ≥0.4 mm |

| Print speed | 30-90 mm/s |

| Recommended build surface treatment | PEI Film |

| Build plate temperature | 80-110°C |

| Raft separation distance | 0.18-0.2 mm |

| Cooling fan speed | 0%-50% |

| Retraction distance | NO |

| Retraction speed | / |

| Recommended Support Material | / |

| Additional Suggestions: | |

| 1.Since ASA-Aero adops the ‘on-demand foaming’ technology, the filament will continue to expand in the nozzle after being heated during the printing process. Therefore, it will cause unavoidable stringing during the nozzle movement. Even adjusting the retraction setting in the slicing software cannot solve this problem. Based on the above, it is recommended to turn off the retraction setting. | |

| 2.Because ASA materials have a high glass transition temperature, a certain ambient temperature(40-70°C) is required during printing to release the internal stress of the printed parts and reduce warping. When printing thin-walled models without any form of insulation, it is recommended to use nozzles with a diameter of 0.6mm or more to ensure the strength of printed parts and reduce shrinkage. | |

| 3.When printing with ASA-Aero filaments, please place the enclosed printer in a ventilated environment. | |

PA12-CF

-

Product Features

- Superior Strength and Stiffness

- Toughness & Vibration Resistance

- Exceptional Thermal Resistance

- Comes with High Temperature Spool

- Diameter: 1.75mm +/- 0.02mm

- 0.2 mm Nozzle Not Compatible

- Brass/Copper plated Nozzle Not Recommended

- Dry before Use

- Enclosed Printer Required

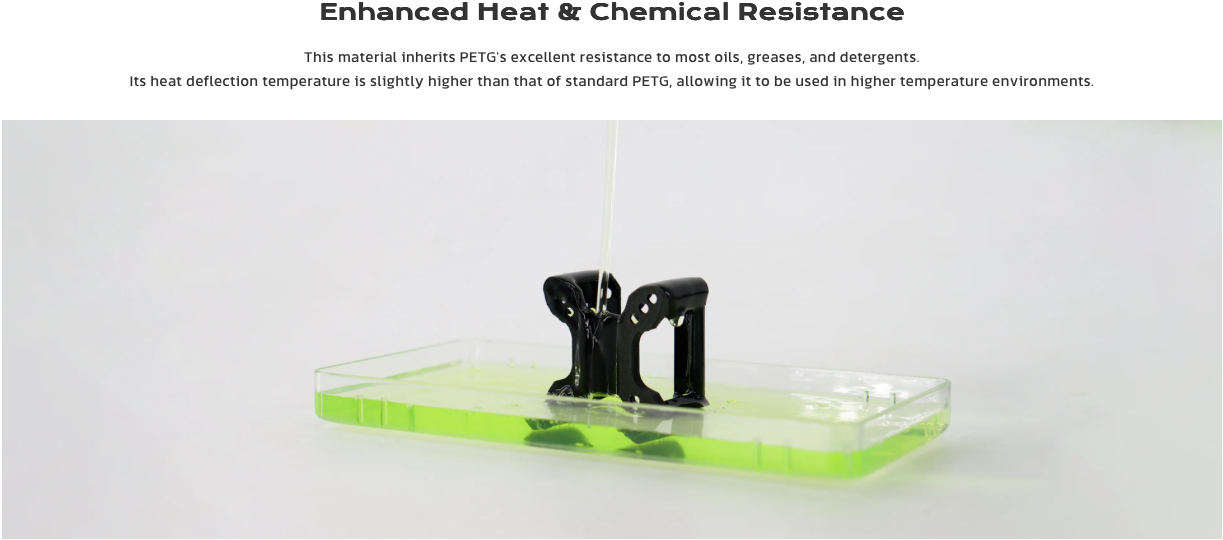

PET-GF

- Very Low Moisture Absorption

- Exceptional Mechanical Properties

- High Dimensional Stability

- Exceptional Thermal Resistance

- Comes with High Temperature Spool

- Diameter: 1.75mm +/- 0.02mm

- 0.2 mm Nozzle Not Compatible

- Brass/Copper plated Nozzle Not Recommended

- Dry before Use

- Enclosed printer (Recommended)

PLA Rapido Metal

- Tough and Durable

- No-paint Metallic Texture

- No Metal particle infill

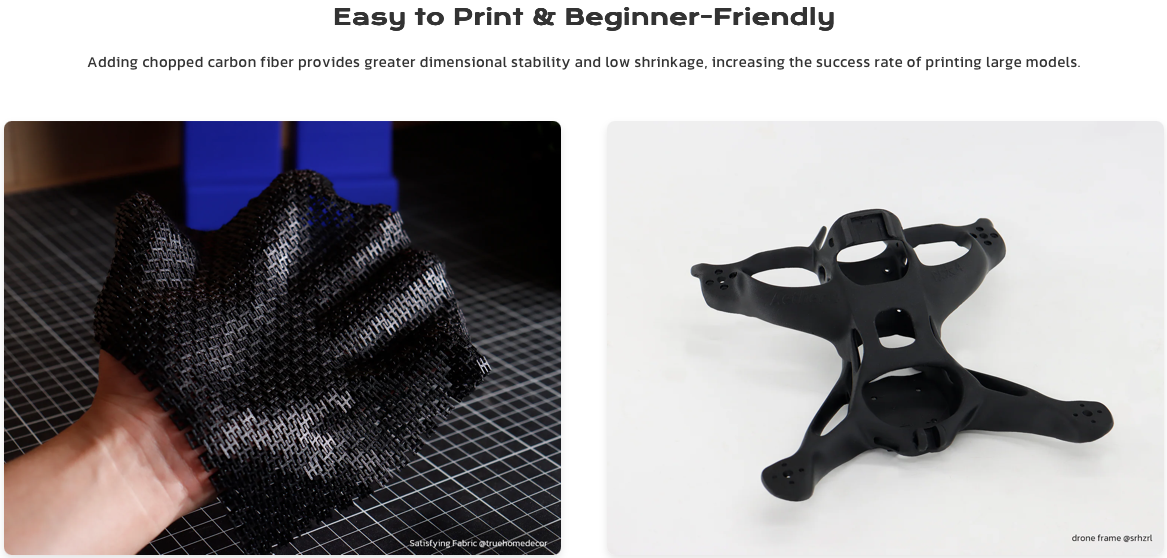

- Easy to Print & Beginner Friendly

- Closed chamber not recommend

1. Reduce print speed: PLA Metal is more viscous than regular PLA. Lower print speeds are recommended to minimize pulling and improve surface smoothness. 2. Use proper substrate adhesion: PLA Metal may be more prone to warping in some cases, so make sure that the print bed is clean and that proper adhesion measures are used (PEI sheet or glue, etc.). 3. Do not print too large overhangs: PLA Metal has a higher fluidity at high temperatures, so when printing overhangs, the material does not easily hold its shape in the air. For more details please refer to: Filament Guide on WIKI.

PLA Wood (Rapido)

- Matte Texture

- Wood-like effect

- Easy to Print & Beginner Friendly

- Diameter: 1.75mm +/- 0.02mm

- Chamber enclosed not recommend

With the addition of natural wood powder, PLA Wood exhibits the following distinct characteristics compared to regular PLA.

1. Higher Moisture Absorption: PLA Wood contains natural wood powder, making it more sensitive to moisture. Dry before use to ensure the best print quality and consistent finish. •Storage and Drying: Although PLA Wood is thoroughly dried and vacuum-sealed prior to shipping, variations in transport conditions may affect its moisture level. We strongly recommend drying it right after opening and storing it in a sealed container with desiccant. Repeat drying and moisture-proofing before each long-term storage period. •Drying Guidelines: For best results, dry at 55 ± 5°C for 8 hours in a blast drying oven.

2. Color Variation: Natural wood powder may result in slight color variations depending on the drying level and raw material differences.

3.Wood-like smell: During printing, PLA Wood emits a mild, natural wood scent due to the wood powder content. It is non-irritating and non-toxic. For more details please refer to: Filament Guide on WIKI.

QIDI PPS-CF 0,75kg

- Heat Resistance Up to 264℃

- Excellent Flame-resistant

- Top-tier Mechanical Properties

- Solvent and Chemical Resistance

- Ultra-Low Water Absorption

- 0.2 mm Nozzle Not Compatible

- Stainless Steel Nozzle Not Recommended

- Must Be Dried before Use to Achieve Optimal Print Quality

PPS-CF is a composite material made from carbon fiber-reinforced polyphenylene sulfide (PPS). The combination of PPS resin with carbon fiber imparts excellent properties to PPS-CF, including outstanding solvent resistance, corrosion resistance, heat resistance, and flame retardancy. Additionally, higher printing temperatures enhance the strength, rigidity, and dimensional stability of PPS-CF. When paired with the QIDI Plus4, it becomes a specialty engineering plastic capable of meeting the demands of unique and challenging applications.

PPS-CF exhibits excellent solvent and chemical resistance. At temperatures below 200°C, it is virtually insoluble in any solvent and demonstrates outstanding resistance to acids, alkalis, and salts under normal conditions. This makes PPS-CF an ideal choice for demanding environments where high chemical stability is essential.-

Description

The excellent weather resistance and mechanical properties make asa filament more resistant to the effects of environmental aging. The asa 3d printer filament is widely used in outdoor applications.Sellingpoint

Weather resistance High toughnessHigh rigidity High impact resistance

Qidi TPU95A-HF

Qidi UltraPA Nylon Filament (PPA)

-

Description

Development based on nylon 6/66 copolymer; Self-lubricating wear resistance makes it suitable for printing gears; High toughness and impact resistance, with an elongation at break of up to 175%, which can print strong and durable parts with high fracture resistance; Low shrinkage, not easy to warp and crack when printing.Sellingpoint

High toughness High impact resistanceSelf-lubricating wear-resisting Excellent printability

QIDI PAHT 1kg

-

Description

PAHT-CF(PPA-CF) is specially developed for FDM 3D printing process, the substrate is made of QIDI UltraPA(PPA),high-temperature nylon with low moisture absorption, high strength, high abrasion resistance, excellent chemical resistance and high heat resistance, good dimensional stability and no warping during the printing process.

ABS-GF25

- 【ABS Filament Filled Glass Fiber - New upgrade】ABS-GF25 adopts a special multi-layer co-extrusion technology. The inner layer is ABS resin filled with 25% high content of glass fiber, and the outer layer is ABS resin with adhesive strength, which can greatly reduce the floating fiber phenomenon on the surface of the model and make the printed parts feel smoother.

- 【Excellent Mechanical Properties】QIDI TECH ABS-GF25 filament 1.75mm is a reinforced composite glass fiber ABS material. ABS glass fiber filament is composed of 75% ABS and 25% glass fiber. It has higher hardness and toughness, and reduces shrinkage, which makes it easier to print and obtain frosted surface texture. ABS glass fiber 1.75 is the ideal choice for high-performance applications.

- 【High Interlayer Bond Strength】On the basis of increasing the content of ABS-GF glass fiber to 25%, a layer of pure ABS resin with high bonding strength is coated on its surface, which retains the original frosting, anti-warping and other characteristics of ABS-GF material, further improves the interlayer bonding performance of the material, and solves the problem that the interlayer strength of ABS-GF filament is weakened.

- 【High Compatiblity & Vacuum Aluminum Foil Pack】QIDI TECH ABS-GF25 3D printing filament is vacuum sealed in a aluminum foil packag to effectively protect the filament from moisture enabling much smoother and more stable printing. Wide compatibility with most 1.75mm Filament FDM Printers on the market.

- 【Tips for Printing】Compatible with most of FDM 3D Printers that use 1.75MM filament. Recommend Extrusion / Nozzle Temp: 250°C - 270°C, Bed Temp: 100°C - 110°C, Fan Speed: Off, Print Speed: 40-200mm/s. It is better to use steel nozzle because the hardness of glass fiber is very high and it is easy to wear copper nozzle.

Product categories

Filter by price

Filter by Color

- Black (15)

- Red (6)

- Yellow (6)

- Ash Grey (1)

- Blue (6)

- Brown (2)

- Cedar Brown (1)

- Clear (2)

- Coffee Gold (1)

- Green (5)

- Grey (5)

- Kraft (1)

- Malt Clay (1)

- Midnight Green (1)

- Natural (3)

- Navy Blue (1)

- Olive Green (1)

- Orange (3)

- Silver (5)

- Tech Grey (1)

- Transparent Black (1)

- Transparent Blue (1)

- Transparent Purple (1)

- Transparent Red (1)

- Transparent Yellow (1)

- Warm Grey (1)

- White (7)

Brands

- QIDI (22)

Store Information

+995 555 271 261

მისამართი: 34 Pekini ave, Tbilisi, Georgia

სამუშაო საათები:

ორშაბათი-შაბათი : 11:00 – 19:00

კვირა – დაკეტილია